Design for non-profit resort for sick kids focuses on color and creativity

The new Towne Hall building at Give Kids The World Village is the fanciful centerpiece of the non-profit resort that provides cost-free, weeklong vacations for children with life-threatening illnesses, and their families. In keeping with the whimsical architecture and child-friendly feeling found throughout the 79-acre resort, the structure is clad in vibrant, primary colors reflecting Towne Hall’s cheerful design and candy-coated theme.

Located in Kissimmee, Fla., Give Kids The World has served more than 140,000 children and families from all 50 states and 75 countries since its founding nearly 30 years ago. The long-awaited 53,000 sq. ft. Towne Hall building was designed by C.T. Hsu & Associates, Orlando, and built by Welbro Building Corp., also in Orlando. The ground floor of the two-story building houses a themed food court and spacious multi-purpose room. Administrative offices are located on the second floor.

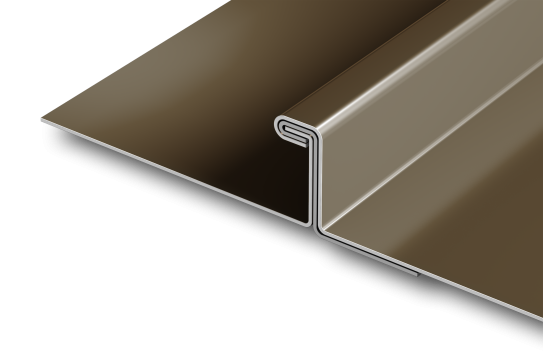

The colorful and creative clock tower that rises above the PAC-CLAD metal roof creates a signature feature that is visible throughout the resort property. Two Petersen Aluminum profiles were selected to achieve the design of the roof and tower. Approximately 6,000 sq. ft. of Petersen Aluminum’s 18-in. Snap-Clad panels were utilized on the roof. The clock tower was created using 1,200 sq. ft. of PAC-150 standing seam metal roof panels. Panels in both profiles are 24 gauge and finished in Patina Green.

Fabrication of all panels was done on-site by Anco Roof System, Fort Myers, while installation was completed by Hartford South in Orlando. “Having the panels formed on-site gave us the benefit of getting the exact panel sizes we needed with virtually no waiting after we field measured,” said Donny Cammenga, Hartford South’s project manager. “That really cut down the installation time.”

Hartford South has considerable experience with the various Petersen Aluminum profiles. “Snap-Clad has all of the uplift approvals but the big benefit is that you don’t have to come back and mechanically seam it—that’s a cost and a time saver. We used the PAC-150 panels on the clock tower because the profile height allowed us to create the radius panels as designed by the architect,” Cammenga said. PAC-150 panels combine semi-structural metal panel performance with architectural aesthetics, and are manufactured only in Petersen Aluminum’s Acworth, Ga., facility.

John Sfier, project executive for GC Welbro Building Corp., was quick to compliment the installer. “The roofing installation went incredibly well. Hartford South was a good partner—they really know what they’re doing,” he said. Sfier also commented on metal roofs in general. “We frequently use standing seam metal roofs on our projects. Metal is a more substantial roofing system that has the looks and the longevity to withstand the weather.”

Both Sfier and Cammenga acknowledged the satisfaction their crews enjoyed from their efforts on a charitable project like Give Kids The World Village. “It was very rewarding to work on such a meaningful project that will provide enjoyment for some very sick kids,” Cammenga said. Sfier echoed the sentiment.