Metal adds a modern look to school’s new main entrance

The high school in Athens, Texas, was facing capacity issues stemming from the area’s growing population, so plans were made to renovate existing space, build new space and connect it all with a pedestrian tunnel. Collaboration between the architect, school officials and the community contributed to the success of the project, which included a large curved sign featuring the school’s name clad in metal panels finished in the school’s custom maroon color.

The existing high school was split between two buildings that were separated by both distance and elevation, explained George DeJohn, project architect/manager, Claycomb Associates Architects in Dallas. “As part of the additions we bridged this gap between buildings so that students could walk indoors continuously between spaces. We also had an opportunity to create a new main entrance that was clearly visible, and give the entire school a new modern façade.”

To create the modern design, metal was chosen, which introduced a material other than masonry to the exterior. Metal also provided an impressive medium on which to prominently feature the school’s custom maroon color on the building’s new main entrance.

“The main entrance was highlighted with a large protruding wall clad with maroon metal composite panels,” DeJohn said. “The wall serves as a waypoint for visitors to find the front door, and also emphasizes the district brand with the school color. We used the same metal panels on a project one year before at the school’s stadium and fieldhouse. Using the same panels re-emphasized that brand. The white and silver metal panels near the entrance and throughout the rest of the exterior serve as a backdrop that helps make the maroon panels stand out.”

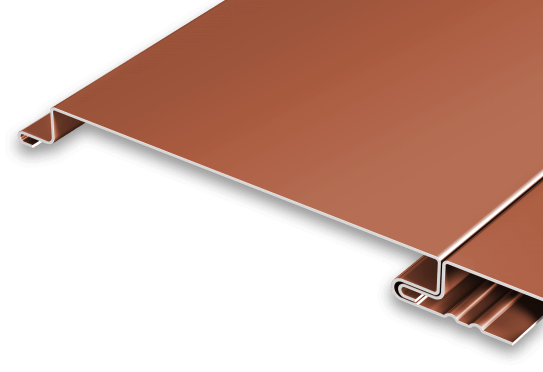

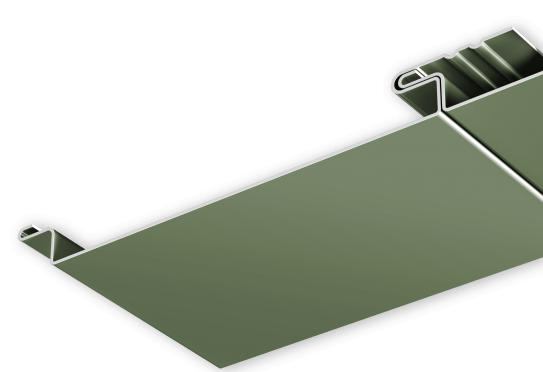

Installed on the school buildings was 10,800 sq. ft. of 24-gauge 12-in. PAC-CLAD Flush Panels in White and Silver finish, 17,500 sq. ft. of 24-gauge 12-in. Flush Soffit panels in White finish, and 5,500 sq. ft. of PAC-3000CS Composite Panel finished in custom maroon color on the school sign and big red wall.

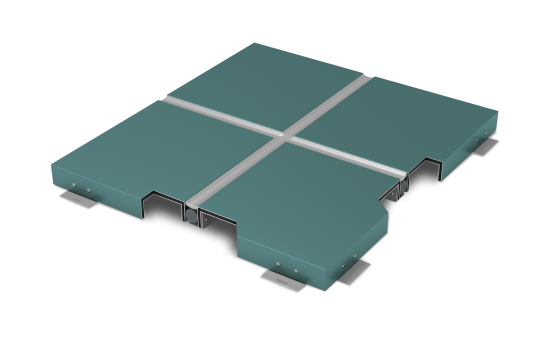

PAC-3000CS is a metal composite material (MCM), also known as aluminum composite material (ACM). The square shapes created by the reveal joints in the ACM panels, not the metal itself, create a modern look for the school, DeJohn explained.

DeJohn’s selection of the various metal cladding panels was never questioned, but the cost was. Ultimately the investment was made for the metal’s ability to create a different look and to signify something special. “Metal was chosen for soffits and walls to break up the school’s façade with something other than brick, and for its durability,” DeJohn said.

In addition to the Petersen ACM panels, the PAC-CLAD Flush Panels were specified to be installed vertically at different locations around the building, which helped create an oversized fascia around the perimeter. The most prominent usage was around all sides of the upper levels of the gymnasium, DeJohn said.

The contracting firm that installed the Petersen metal also played a role in its selection, said Dwayne Maynard, superintendent, project manager and estimator at Heritage One Roofing in Dallas. “The general contractor asked us which material we would like to work with and I recommended Petersen. We had used the same color ACM panels on the same school’s field house the prior year and we were familiar and comfortable with the product.” Heritage One Roofing was on site for roughly eight months, which included roof installation.

Because construction took place on an active campus, crews had to work while school was in session. This meant DeJohn and Maynard’s teams established critical phasing and other coordination with the school administration to avoid disrupting the school year. In addition to expanding the core spaces of the existing high school to accommodate the school’s student population, DeJohn’s team also added a new dining space, kitchen, gymnasium, and career/technical education building.

Challenging curves

The school’s main entrance and the sign in front of the building are curved, which presented challenges for the Heritage One Roofing team. “The ACM panels went up, over and down the back side of the sign so the top panel had to be tapered because the sign is wider in the back. It worked out well because the panel fabrication was spot on,” Maynard said. “The big red wall on the school’s main entrance was square with no radius to it so that was pretty straightforward. On the walls surrounding the main entrance, the length of the trim pieces had to be adjusted to accommodate the building’s curve but that worked out fine, too.”

Soffits around the main entrance also were curved, which meant Maynard’s team had to pie-piece the panels together. “We calculated where to put the joints and lined them up with lighting fixtures. We worked with the owner a lot on this, who had the last say on design aspects, colors, and joints. The architect was involved, too, and ultimately the plan was approved,” Maynard recalls.

Both Maynard and DeJohn have installed and specified PAC-CLAD products for years because of the trusted name, they said. “I love the Petersen service, the people are helpful and the technical information I need is accurate and is provided right away,” Maynard explained.

Petersen’s national manager of technical services Josh Jacobi became involved at one point to discuss the benefits of applying pencil ribs to certain panels to minimize oil-canning and to give the metal a more pleasing appearance. “Vertical panels will always attract more attention, both positive and negative, therefore, trying to utilize available options for a panel to help in that appearance is always a positive. Addressing the problem before installation is critical to avoid any issues later for all parties,” Jacobi said.

Maynard appreciated Jacobi’s support. “When a manufacturer like Petersen backs up an installer like me it helps a lot, and it lets the owner know that sometimes real issues arise, and not because a contractor is being lazy or compensating for messing up on measurements. Petersen’s support is very valuable.”

Petersen, a Carlisle company, manufactures PAC-CLAD architectural metal cladding products in multiple gauges of steel and aluminum. PAC-CLAD products include standing seam roof panels, hidden- and exposed-fastener wall panels, flush- and reveal-joint panels, vented or solid soffit panels, perforated metal, coil and flat sheet, composite panels, column covers, plus fascia and coping. All are available in Kynar 70% PVDF finish in 45 standard colors that include a 30-year finish warranty. Most colors meet LEED requirements and are rated by the Cool Roof Rating Council. Custom colors and weathertightness warranties are offered. Founded in 1965, Petersen’s facilities are located in Illinois, Georgia, Texas, Maryland, Arizona, and Minnesota. For information on the complete line of Petersen metal products call 800-PAC-CLAD, visit pac-clad.com or write to [email protected].

Editors: If photos are published the following credit is required: Photos: buenavistaphotography.com