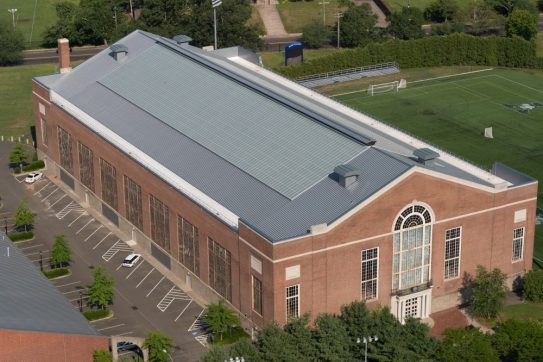

The venerable Coxe Cage field house at Yale University remains an integral part of the school’s track and field history thanks to the building’s new roof. Although the old cinder track and dirt floor were replaced with modern surfaces in 1982, the roof and its large, single-glazed skylight – both of which had deteriorated badly and needed replacing – had remained largely untouched for 80 years, until late 2013.

Built in 1928, the Cage was named for Charles Edmund Coxe, a hammer thrower on Yale’s squad. The story goes that Coxe, who was charged with raising funds for the new facility, offered the necessary $300,000 with the stipulation that it be named for him. Construction began on what then was considered one of the largest structures of its kind in the world. Measuring more than 350 feet long and 156 feet across with a ceiling reaching nearly 83 feet high, the building encloses more than 3.3 million cubic feet of air space.

The University hired Kiss + Cathcart Architects in Brooklyn, N.Y., to lead an evaluation of the technical feasibility, energy performance, aesthetics and cost of various envelope and mechanical upgrades and replacements. After review of the options and alternatives, it was determined that the first phase of renovation would concentrate on the roof and skylight.

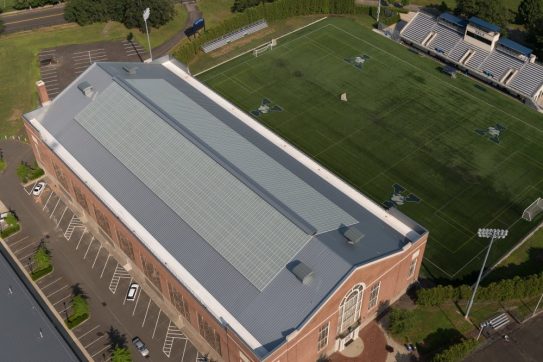

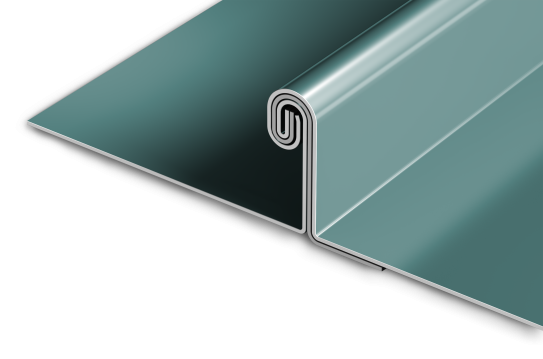

Approximately 26,000 sq. ft. of Petersen Aluminum .040 aluminum Tite-Loc Plus panels were utilized on the project. The 16-inch O.C. panels were finished in PAC-CLAD Cool Color Zinc.

“This was a fairly complex roof,” said architect Colin Cathcart. “It included a ridge ventilator unit, giant vent fans and, of course, the massive skylight. The roof has enormous scale compared to most roof installations.”

The design team initially considered other roofing materials but settled on metal because of the life span, low maintenance and the look. “The view of the building and roof from the adjoining Yale Bowl was an important consideration,” Cathcart said. “We felt the standing seam panels interfaced nicely with the new skylight to retain the historical appearance. The metal matched up functionally and aesthetically with the performance of the skylight and the flashings, gutters and parapets.”

The Petersen roof was installed by Silktown Roofing, Manchester, Conn. The majority of the Tite-Loc Plus panels were 72-feet long. “Getting those long panels up on the roof by crane and landing them on a 7/12 slope was a real challenge,” said Steve Pumphrey, project manager. “The old roof was removed down to the existing tongue-and-groove decking. Then we stitched all of the decking boards with fasteners, installed an ice and water shield, then nailboard, and then another ice and water shield. But the toughest part was getting the long panels up there. Once that occurred, the job was relatively straightforward. Everybody loves it.”

Architect Colin Cathcart reiterated the challenges of the job. “It was an amazing logistical accomplishment necessitated by the scale of the roof,” Cathcart said. “Matching up all of the systems was really the primary design challenge. The overall installation went cleanly.”

The Petersen distributor was ABC Supply, Hartford, Conn. The general contractor on the project was Giordano Construction Company, Branford, Conn. The skylight was provided by E-Skylight Inc., Branford, CT.