Two metal panels add style to new Alabama community activity center

Residents of eastern Tuscaloosa County, Ala., had long felt neglected in the county’s planning efforts when discussions began for a new activity center. It took four years and two different building plans, but those locals now have a $5 million facility they can be proud of. Incorporating a pool – complete with an indoor/outdoor water slide – along with fitness and multipurpose rooms, the center also features an attractive exterior design that highlights the eye-catching options metal wall panels can offer.

Now named the Jerry Tingle Activity Center after the county commissioner who championed its construction, the 18,500-sq-ft. facility is one of seven operated by the Tuscaloosa County Park and Recreation Authority. It’s sited in the unincorporated community of McCalla, Ala., a previously rural area of the county that’s now expanding quickly. Within a month after its opening, the activity center had garnered at least 500 family memberships.

Designers with Ellis Architects initially had proposed a purpose-built structure with a masonry exterior to county commissioners. When costs came back, however, they proved to be higher than the budget would allow. Going back to their drawing boards, the design team opted for a prefabricated metal building. The building package already included metal roofing, and the architects selected a combination of panel profiles to add visual punch to the façade.

“They were wanting a contemporary look, not like a traditional metal building,” says Eric Requist, a senior project architect with the design firm. “We tried to do that by breaking up the structure the [water] slides come out of.”

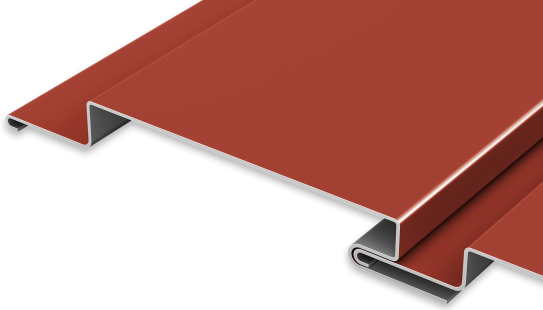

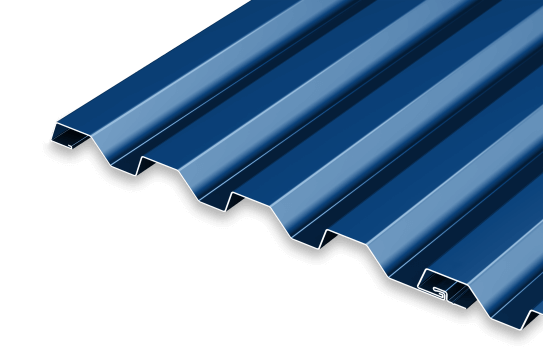

Specifically, the plan pairs 8,100 sq. ft. of Petersen’s PAC-CLAD Reveal Panels in a Sandstone finish with 6,500 sq. ft. of the company’s HWP panels – all in .024-gauge aluminum. Requist says getting the mix of the two styles just right was more art than science.

“You play around with different textures, and the different proportions of those textures, until you think to yourself it looks aesthetically pleasing,” he says. “The intent was to find a balance between the two, using the tighter, undulating panel as an accent.”

Ensuring the panel lines remained continuous around the building took a little extra time for the installation pros from Birmingham, Ala.-based R. B. Atkins & Associates. “One of the unique things in this project is they mixed up the panels all over the surface of the building,” says Brian Atkins, the company’s president. “One of the factors was where the windows and doors were located. We had to run a control line all around the building, so we stayed level – we used a level out in the field, like surveyors use.”

Those field measurements then were incorporated into the R.B. Atkins shop drawings, which were approved as submitted by Requist’s design team. The finished project seems to have met with approval by both the local community and the installers, themselves, according to R. B. Atkins project manager and estimator Doug Shaw. “We were wondering how it was going to look when it was finished,” he says. “We think it turned out pretty good.”

Both architects and installers were equally upbeat in discussing their experience working with Petersen on the job.

“They’re always good to work with,” Requist says, who noted that he has a long history of working with metal panels in general, and Petersen materials specifically. “I know that if I hadn’t had the experience, they could have helped me out as they did years ago.”

Atkins sums up the Petersen advantage simply: “Good people, good products and good service.”

Photo by: hortonphotoinc.com