New Timber Series wood grain finishes enhance creative design options

The new PAC-CLAD Timber Series wood grain finishes from Petersen includes a range of colors from rich browns to shades of gray and white. The simulated PVDF finishes can be [Read More]

Petersen adds SPS Metals as a PAC-CLAD distributor in Colorado

Petersen has added SPS Metals as a distributor of its PAC-CLAD architectural metal cladding systems in Colorado. Effective immediately, SPS Metals will begin distributing PAC-CLAD painted sheet metal to customers [Read More]

Standout metal roof proves its mettle during hurricane Ian

Port Orange, Fla., might be a standout location in the middle of Florida’s Fun Coast, 10 minutes from Daytona Beach, but homes there also must be designed to stand up [Read More]

Price increase June 3 for aluminum coil, sheet and panels

Because of the increase in aluminum ingot costs, Petersen is implementing a price increase on the following aluminum products effective June 3, 2024: • Painted coil and flat sheets: 6% [Read More]

Price increase effective May 20 for underlayment

Due to inflationary pressures and the rising cost of raw materials in the building industry, Petersen Aluminum will be implementing a price increase up to 6% on PAC-CLAD HT Underlayment [Read More]

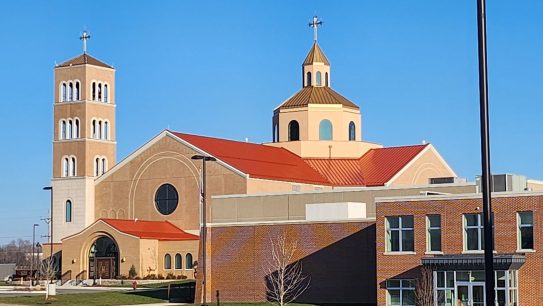

Catholic church’s terra-cotta metal roof follows Northern Italy styling

At a time when many churches are facing declining attendance, St. Charles Borromeo Catholic Church in Hartland, Wis., was bursting at the seams when its leaders determined a new, larger [Read More]

Metal wall panels add streamlined appeal to new rural hospital

At a time when rural hospitals are closing across the United States, it’s heartening to hear of a new facility opening in Tippah County, Miss. – population 21,815, according to [Read More]

Price increase Feb. 12 for steel coil, sheet and panels

The steel market continues to see upward pressure on raw material costs. As such, it is necessary to implement a price increase on the following products effective February 12, 2024: [Read More]

Metal panels create streamlined good looks at new medical building

DeSoto County is Mississippi’s fastest growing county, and construction there is booming. A case in point is the city of Southaven, an easy commute to nearby Memphis, Tenn., which saw [Read More]

Metal panels add panache to new Georgia elementary school

Bleckley County, Ga., advertises itself as one of the “best-kept secrets” in Middle Georgia, and photos show the largely rural district offers loads of opportunities for outdoor activities. And, while [Read More]