Robin Thompson joins Petersen as PNW sales manager

Petersen is pleased to announce that Robin Thompson is now the Pacific Northwest Regional Sales Manager for its PAC-CLAD brand of architectural metal cladding systems. Thompson assumes the role effective [Read More]

New utilities building ups the style ante with metal wall panels

For evidence of Arizona’s status as one of the nation’s fastest-growing states, consider the Phoenix exurb of Queen Creek. Located just outside that city’s metropolitan area, its population grew to [Read More]

Price increase on steel effective May 1, 2023

Raw material costs from domestic steel suppliers are increasing, and therefore Petersen Aluminum is implementing a price increase on the following products effective May 1, 2023: • Steel coil, flat [Read More]

Division 7 Sales rep group hired for KS and MO

Petersen has hired manufacturer’s rep group Division 7 Sales to cover the PAC-CLAD market in Kansas and Missouri. Firm leader Danny Bryson has more than three decades of experience leading [Read More]

Roofing Representatives rep group hired for NE and IA

Petersen has hired manufacturer’s representative Jason Smith and his team at Roofing Representatives as the PAC-CLAD independent sales representatives firm in Nebraska and Iowa. Roofing Representatives’ main office is in [Read More]

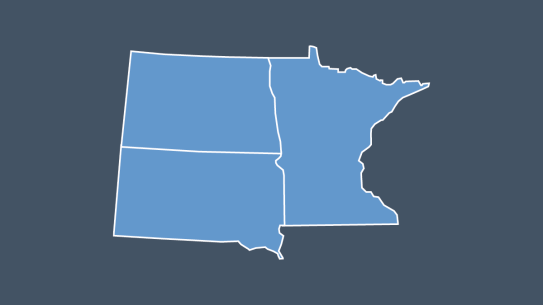

Shermach Sales rep group hired for MN, ND and SD

Petersen has hired the newly formed rep group Shermach Sales to over its PAC-CLAD customers in Minnesota, North Dakota and South Dakota. Chris Shermach will lead the team, and has [Read More]

Appliance store sports retro appeal from perforated metal

Big-box stores have become a go-to resource for home appliance and electronics shoppers who think those outlets’ sales volumes are a guarantee of lower prices. But regional, family-owned chains can [Read More]

New sales rep introduced for PAC-CLAD in MN, ND and SD

Shermach Sales is the new sales representative for PAC-CLAD products in Minnesota, North Dakota and South Dakota. Chris Shermach will work from within his three-state territory as he builds a [Read More]

Modern farmhouse facelift topped by eye-catching metal panels

The modern farmhouse look has ruled American home design for almost a decade, and doesn’t show signs of letting up. And, unlike other approaches – like modern/contemporary or strictly traditional [Read More]

Metal, wood and stone add contemporary flair to revitalized suburban office park

Commercial office parks took off in the 1960s and 1970s as corporations sought to create their own campus-like communities, separate from the downtown city cores they’d once called home. They [Read More]