PAC Snap Edge Fascia: PAC Snap Edge BUM

Metal Roofing Fascia SystemsFeatures

Features

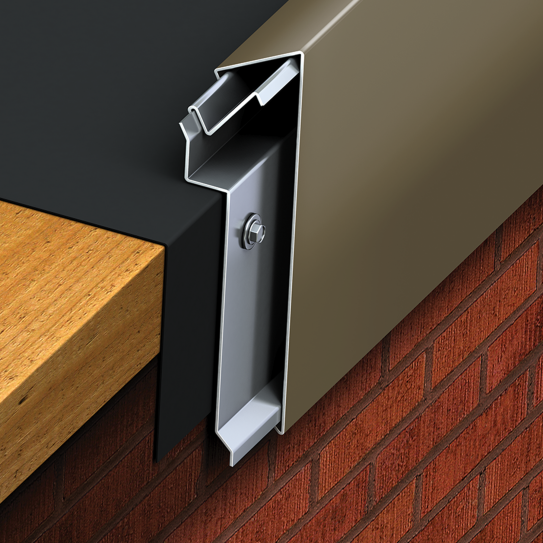

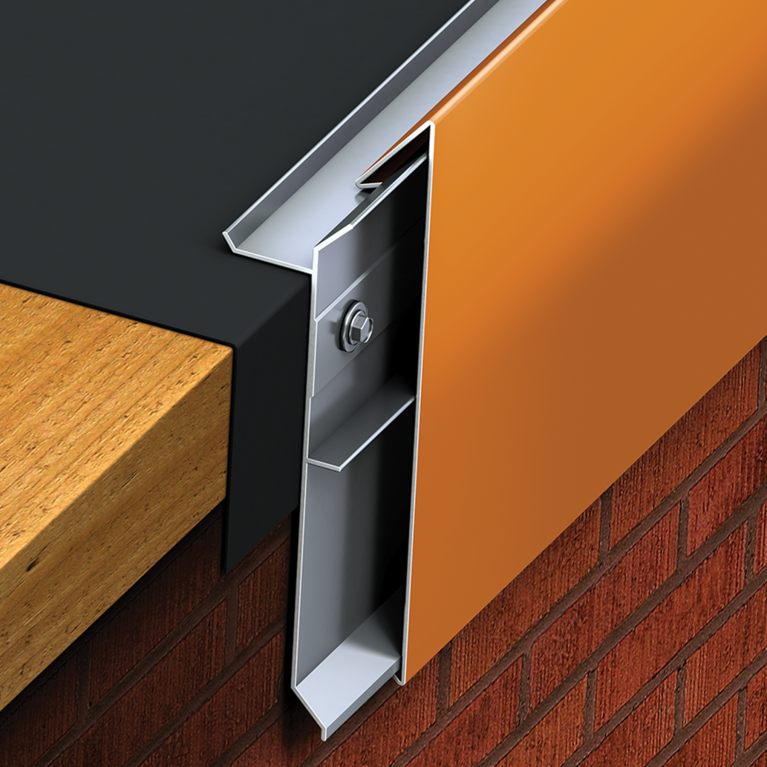

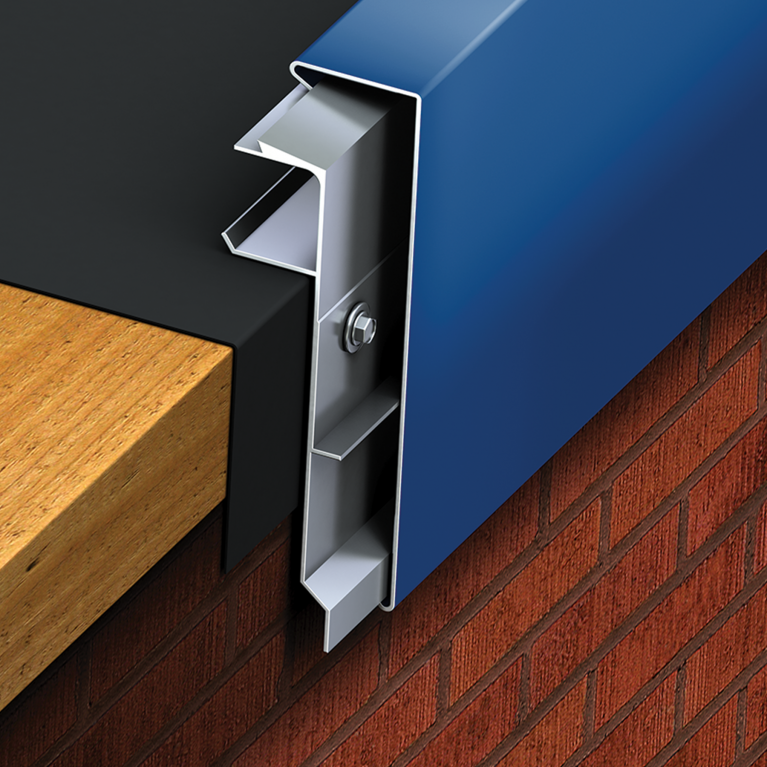

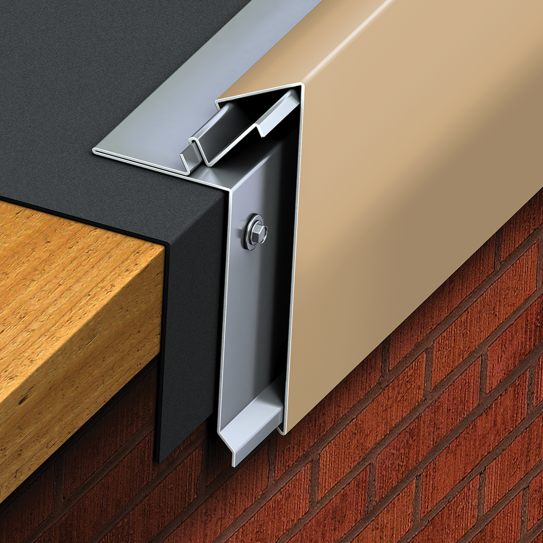

Profile Variations

Click a profile image to view that profile.

With PAC Snap Edge Fascia, outstanding protection against wind up-lift damage for flat roof installations meets superior economy and ease of installation. PAC Snap Edge is the ideal solution for keeping roof edge projects on schedule and on budget while meeting the rigorous standards of ANSI/SPRI ES-1 standards.

Installation is fast and easy, featuring a snap-on cover to eliminate field crimping, and an efficient design that does not require stripping in or heat welding. The product is produced in 12′ lengths for an estimated 20% – 40% savings in material handling over the typical 8′ and 10′ lengths.

Three Versions Available

All versions of PAC Snap Edge are available, in face sizes up to 8″:

- Fully Adhered/Mechanically Attached Single-Ply (FA)

- Stone Ballast Single-Ply (SB)

- Built-Up/Modified (BUM)

PAC Snap Edge features pre-punched holes which not only provides quicker installation for labor savings, but are slotted to allow for thermal movement for guaranteed long-term performance. Competitively priced, PAC Snap Edge ensures a consistent, high quality, low-cost factory engineered product on every project.

Offering a wide range of factory-fabricated accessories such as miters, scuppers and drainage components, Petersen provides the complete system to ensure a clean, sure-fitting product while eliminating the need for field fabrication.

With PAC Snap Edge Fascia, outstanding protection against wind up-lift damage for flat roof installations meets superior economy and ease of installation. PAC Snap Edge is the ideal solution for keeping roof edge projects on schedule and on budget while meeting the rigorous standards of ANSI/SPRI ES-1 standards.

Installation is fast and easy, featuring a snap-on cover to eliminate field crimping, and an efficient design that does not require stripping in or heat welding. The product is produced in 12′ lengths for an estimated 20% – 40% savings in material handling over the typical 8′ and 10′ lengths.

Three Versions Available

All versions of PAC Snap Edge are available, in face sizes up to 8″:

- Fully Adhered/Mechanically Attached Single-Ply (FA)

- Stone Ballast Single-Ply (SB)

- Built-Up/Modified (BUM)

PAC Snap Edge features pre-punched holes which not only provides quicker installation for labor savings, but are slotted to allow for thermal movement for guaranteed long-term performance. Competitively priced, PAC Snap Edge ensures a consistent, high quality, low-cost factory engineered product on every project.

Offering a wide range of factory-fabricated accessories such as miters, scuppers and drainage components, Petersen provides the complete system to ensure a clean, sure-fitting product while eliminating the need for field fabrication.