PAC T-250

Metal Roofing PanelsFeatures

Features

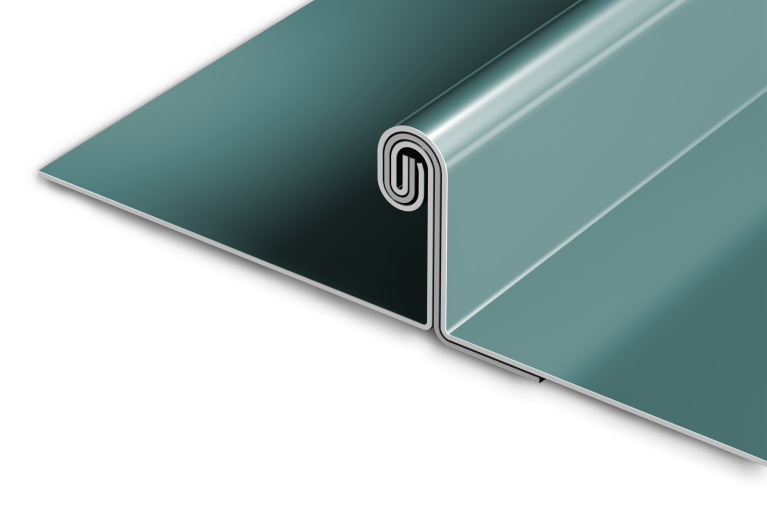

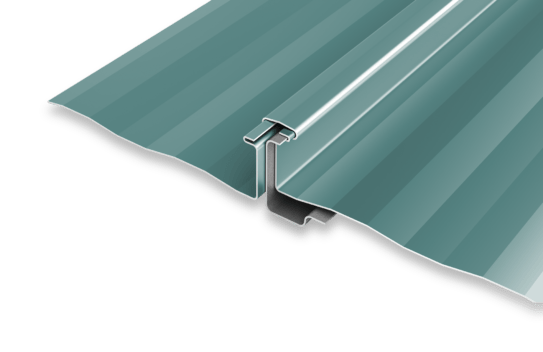

PAC T-250 metal roof panels are factory-formed or field-formed to length and field-seamed. The panels have been designed for application over a wide variety of substrates on roof slopes as low as 1/2 : 12. PAC T-250 panels can be produced in 22 and 24 gauge steel or .032 and .040 aluminum. The PAC T-250 panel combines structural performance with architectural aesthetics. PAC T-250 panels feature a 2.625” nominal finished panel height from the deck that requires mechanical field seaming after installation. The panels have a continuous and/or intermittent concealed-fastener clip system designed to allow for thermal expansion/contraction. Sealant beads are factory-applied to the seam cover.

Trim

All flashing and trim shall be fabricated by Petersen or a qualified fabricator. Flashing shall be PAC-CLAD aluminum or steel. A 35-year non-prorated finish warranty can be supplied covering finish performance. Vinyl film is recommended on all fabrication applications where extra handling is expected. NOTE: The strippable film must be removed immediately after installation.

Installation

PAC T-250 panels are intended for use in architectural and structural roofing. Substrates may include 5/8” min. plywood, nailboard insulation or equal with an underlayment of ice and water shield applied horizontally from eave to ridge. Other substrates may include metal decking, purlins or rigid insulation in conjunction with bearing plates. Contact Petersen for further assistance with installation details. For coastal applications, aluminum panels along with stainless steel clips must be used to qualify for warranty. Consult a local architect/engineer for compliance with local codes and conditions.

The T-250 panel is bi-directional, which allows installers to position the first panel in the center of a roof and install simultaneously in both directions, making it easy to achieve an attractive symmetrical look, while allowing multiple crews to work at the same time.

Seaming

PAC T-250 panels require the use of mechanical seamers, which are available along with hand crimpers and other tools through D.I. Roof Seamers, which is the only supplier of this equipment approved by Petersen. For details and rental information, click here.

PAC T-250 metal roof panels are factory-formed or field-formed to length and field-seamed. The panels have been designed for application over a wide variety of substrates on roof slopes as low as 1/2 : 12. PAC T-250 panels can be produced in 22 and 24 gauge steel or .032 and .040 aluminum. The PAC T-250 panel combines structural performance with architectural aesthetics. PAC T-250 panels feature a 2.625” nominal finished panel height from the deck that requires mechanical field seaming after installation. The panels have a continuous and/or intermittent concealed-fastener clip system designed to allow for thermal expansion/contraction. Sealant beads are factory-applied to the seam cover.

Trim

All flashing and trim shall be fabricated by Petersen or a qualified fabricator. Flashing shall be PAC-CLAD aluminum or steel. A 35-year non-prorated finish warranty can be supplied covering finish performance. Vinyl film is recommended on all fabrication applications where extra handling is expected. NOTE: The strippable film must be removed immediately after installation.

Installation

PAC T-250 panels are intended for use in architectural and structural roofing. Substrates may include 5/8” min. plywood, nailboard insulation or equal with an underlayment of ice and water shield applied horizontally from eave to ridge. Other substrates may include metal decking, purlins or rigid insulation in conjunction with bearing plates. Contact Petersen for further assistance with installation details. For coastal applications, aluminum panels along with stainless steel clips must be used to qualify for warranty. Consult a local architect/engineer for compliance with local codes and conditions.

The T-250 panel is bi-directional, which allows installers to position the first panel in the center of a roof and install simultaneously in both directions, making it easy to achieve an attractive symmetrical look, while allowing multiple crews to work at the same time.

Seaming

PAC T-250 panels require the use of mechanical seamers, which are available along with hand crimpers and other tools through D.I. Roof Seamers, which is the only supplier of this equipment approved by Petersen. For details and rental information, click here.