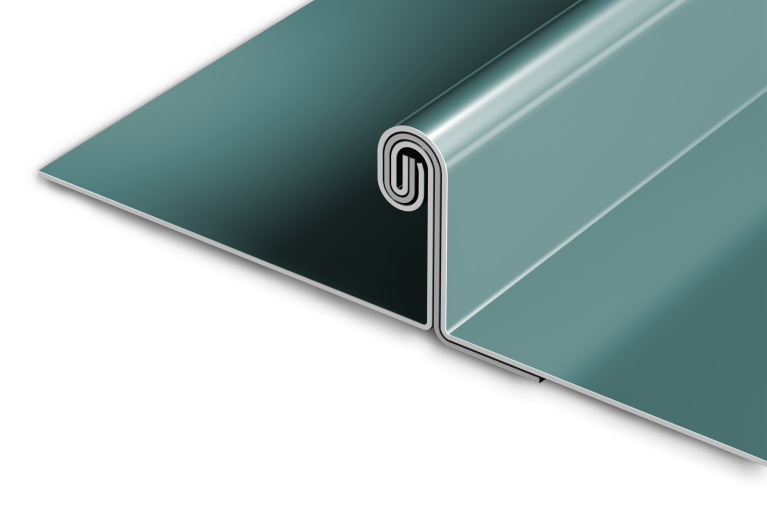

PAC-150 90° Seam

Metal Roofing PanelsFeatures

Features

PAC-150 standing seam metal roofing panels combine semi-structural metal panel performance with architectural roofing panel aesthetics. PAC-150 roofing coil for field-forming operations is leveled to provide superior panel flatness. Maximum panel length is limited when factory or shop-formed but virtually unlimited when field-formed; minimum panel length is approximately 4’.

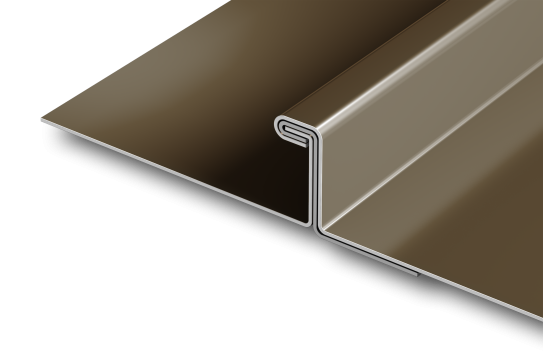

PAC-150 roofing panels feature a 1.5” leg height which requires mechanical field seaming to either 90° or 180° depending on the project’s uplift requirements. Panels have a concealed-fastener clip designed to allow for maximum design flexibility. For further details, please contact a Petersen rep.

This panel combines an attractive thin-rib profile with superior structural performance. PAC-150 panels are designed for application over a wide variety of substrates in slopes as low as 1:12 pitch. PAC-150 roofing panels are available in a wide variety of widths from 12” to 20”. Materials available include 24 gauge steel plus .032 aluminum.

Regional Availability

PAC-150 is produced only in Georgia, Maryland and Arizona facilities; additional freight charges might apply.

Curved Applications

The PAC-150 panels can be curved to a minimum radius of 20’. Curving can be done in the field or at the factory depending on the radius and length of the panel. For details about curving capabilities, please contact the Acworth, Ga., or Annapolis Junction, Md., factories.

Seamers

PAC-150 panels require the use of mechanical seamers. When seaming panels on slopes greater than 6:12, caution must be exercised to prevent seamer slippage and resulting finish scratches that may void the warranty. Seamers are available along with hand crimpers and other tools through D.I. Roof Seamers, which is the only supplier of this equipment approved by Petersen Aluminum. For details and rental information Click Here.

Metal Roofing - How to install PAC-150 90° Single Lock

PAC-150 standing seam metal roofing panels combine semi-structural metal panel performance with architectural roofing panel aesthetics. PAC-150 roofing coil for field-forming operations is leveled to provide superior panel flatness. Maximum panel length is limited when factory or shop-formed but virtually unlimited when field-formed; minimum panel length is approximately 4’.

PAC-150 roofing panels feature a 1.5” leg height which requires mechanical field seaming to either 90° or 180° depending on the project’s uplift requirements. Panels have a concealed-fastener clip designed to allow for maximum design flexibility. For further details, please contact a Petersen rep.

This panel combines an attractive thin-rib profile with superior structural performance. PAC-150 panels are designed for application over a wide variety of substrates in slopes as low as 1:12 pitch. PAC-150 roofing panels are available in a wide variety of widths from 12” to 20”. Materials available include 24 gauge steel plus .032 aluminum.

Regional Availability

PAC-150 is produced only in Georgia, Maryland and Arizona facilities; additional freight charges might apply.

Curved Applications

The PAC-150 panels can be curved to a minimum radius of 20’. Curving can be done in the field or at the factory depending on the radius and length of the panel. For details about curving capabilities, please contact the Acworth, Ga., or Annapolis Junction, Md., factories.

Seamers

PAC-150 panels require the use of mechanical seamers. When seaming panels on slopes greater than 6:12, caution must be exercised to prevent seamer slippage and resulting finish scratches that may void the warranty. Seamers are available along with hand crimpers and other tools through D.I. Roof Seamers, which is the only supplier of this equipment approved by Petersen Aluminum. For details and rental information Click Here.