Snap-On Standing Seam

Metal Roofing PanelsFeatures

Features

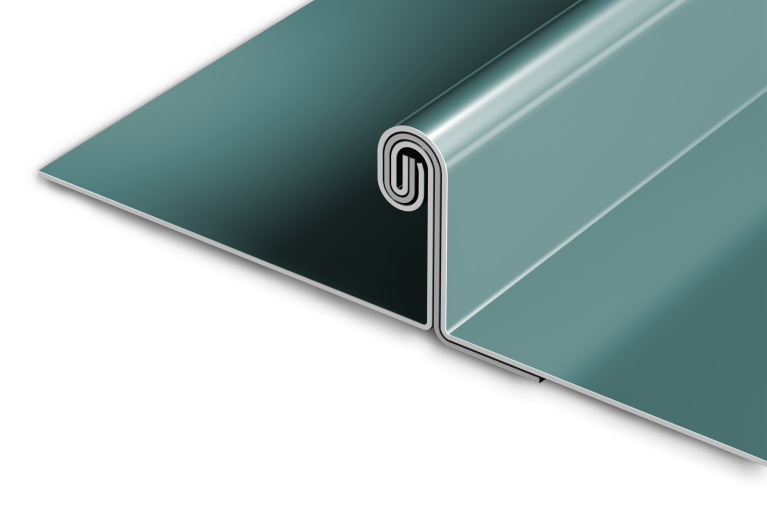

Snap-On panels are ideal for use in roofing, mansard and fascia applications. Snap-On panels are designed to be installed over a waterproofed solid substrate and a minimum 3:12 roof pitch. Snap-On panels are factory roll-formed in continuous lengths. Maximum panel length is 35’ and minimum panel length is 4’. Consult factory for nonstandard lengths.

The simplicity of the pan design combined with leveling provides superior flatness and allows for greater workability on site.

Trim

All flashing and trim shall be fabricated by manufacturer or qualified fabricator. Flashing shall be PAC-CLAD aluminum (.032 – .063 gauge as specified) or PAC-CLAD steel (24 gauge or 22 gauge as specified). A 35-year non-prorated finish warranty can be supplied covering finish performance. Vinyl masking is recommended on all fabrication applications where extra handling is expected. NOTE: The strippable film must be removed immediately after installation.

Installation

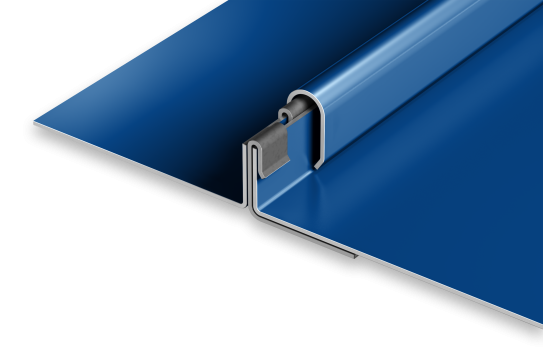

Snap-On panels shall be installed over solid decking (5/8” plywood, nailboard insulation or equal) with an underlayment applied horizontally from eave to ridge. Panels shall be fastened using Petersen nonpenetrating clips, fastening on 18” centers (max.). Minimum slope at 3:12 pitch. Consult a local architect or engineer for requirements of local codes and conditions.

Curved Panels

The 1” Snap-On standing seam panel can be curved to a concave or convex radius, with a minimum radius of 9’. This panel is ideal for barrel vaults and entrance ways. Curved panels must be installed over a waterproofed solid substrate.

How to install Snap-On Standing Seam Panel

Snap-On panels are ideal for use in roofing, mansard and fascia applications. Snap-On panels are designed to be installed over a waterproofed solid substrate and a minimum 3:12 roof pitch. Snap-On panels are factory roll-formed in continuous lengths. Maximum panel length is 35’ and minimum panel length is 4’. Consult factory for nonstandard lengths.

The simplicity of the pan design combined with leveling provides superior flatness and allows for greater workability on site.

Trim

All flashing and trim shall be fabricated by manufacturer or qualified fabricator. Flashing shall be PAC-CLAD aluminum (.032 – .063 gauge as specified) or PAC-CLAD steel (24 gauge or 22 gauge as specified). A 35-year non-prorated finish warranty can be supplied covering finish performance. Vinyl masking is recommended on all fabrication applications where extra handling is expected. NOTE: The strippable film must be removed immediately after installation.

Installation

Snap-On panels shall be installed over solid decking (5/8” plywood, nailboard insulation or equal) with an underlayment applied horizontally from eave to ridge. Panels shall be fastened using Petersen nonpenetrating clips, fastening on 18” centers (max.). Minimum slope at 3:12 pitch. Consult a local architect or engineer for requirements of local codes and conditions.

Curved Panels

The 1” Snap-On standing seam panel can be curved to a concave or convex radius, with a minimum radius of 9’. This panel is ideal for barrel vaults and entrance ways. Curved panels must be installed over a waterproofed solid substrate.