Flush Wall Panels

Flush & Reveal Wall PanelsFeatures

Features

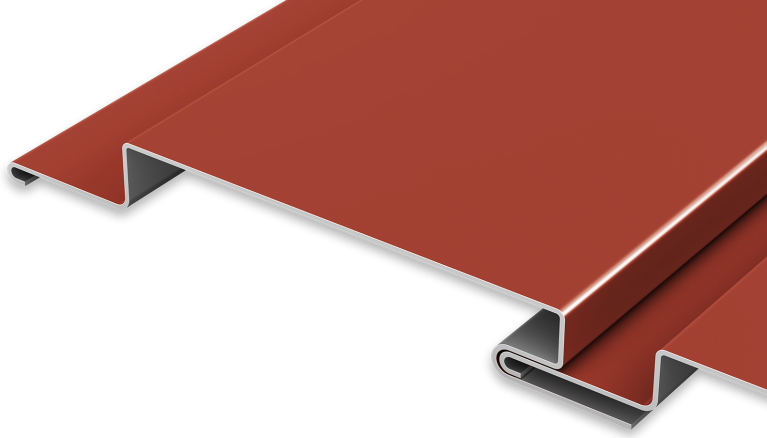

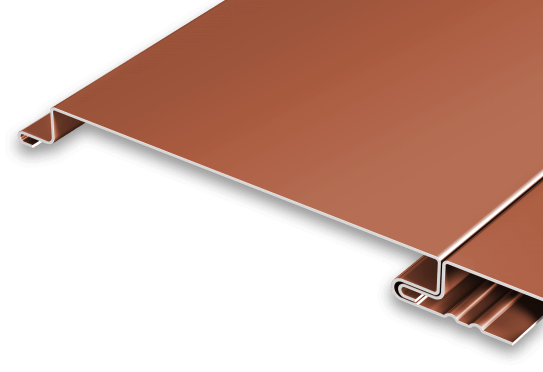

Flush panels are designed for wall, fascia and soffit applications where a flush or flat appearance is desired. A rounded interlock leg and concealed fastening system improves the flush appearance while providing additional strength. Panels are factory-formed to length to minimize field cutting. Maximum panel length is 25’ and minimum panel length is 4’.

Flush panels are available in on-center dimensions designed to complement Petersen’s roofing panel product line.

Pencil ribs

The Flush panels are available with optional pencil ribs. Pencil ribs are recommended for longer panel lengths. One or two ribs are available.

Installation

Flush panels shall be installed over a solid substrate with appropriate ice and water shield, or in limited applications over framing sections. When used in a windscreen application, panels must be fastened (stitched) through side joints. Consult a local architect/engineer for requirements of local codes and conditions.

Leveling

Petersen’s Flush panels are formed on precision roll-forming equipment that includes levelers. Leveling removes typical metal conditions including coil set, crowning and edge wave. Leveling is available at no extra charge.

Trim

All flashing and trim shall be fabricated by manufacturer or qualified fabricator. Flashing shall be PAC-CLAD aluminum (.032 – .063 gauge as specified) or PAC-CLAD steel (24 gauge or 22 gauge as specified). A 30-year non-prorated finish warranty can be supplied covering finish performance. Vinyl masking is recommended on all fabrication applications where extra handling is expected.

Optional clip

An optional patented concealed fastening clip is available to raise a panel assembly’s wind resistance performance level. The optional clip has been designed and tested to resist disengagement during high-wind events (clips were tested only on the 12-inch panel but can be used on all widths); consult Petersen factory rep for details.

Made from 24 gauge stainless steel, the clip is designed for use with PAC-CLAD Flush panels. Clips should be installed at the desired spacing per the product load table for the wind resistance requirements of the project.

The optional concealed clip, which is not visible when the installation is complete, is ideal for installations with higher wind-loading requirements that cannot be met without the clip. The clip can be installed on all substrate materials. The clip has passed multiple performance tests and earned Florida Product Approval. The clips are not to be used to reduce oil canning but rather to strengthen the panel in high-wind applications.

NOTE: Consult with Petersen rep or nearest manufacturing facility before specifying this clip.

Metal Roofing - Flush Panel Concealed Clip

Flush panels are designed for wall, fascia and soffit applications where a flush or flat appearance is desired. A rounded interlock leg and concealed fastening system improves the flush appearance while providing additional strength. Panels are factory-formed to length to minimize field cutting. Maximum panel length is 25’ and minimum panel length is 4’.

Flush panels are available in on-center dimensions designed to complement Petersen’s roofing panel product line.

Pencil ribs

The Flush panels are available with optional pencil ribs. Pencil ribs are recommended for longer panel lengths. One or two ribs are available.

Installation

Flush panels shall be installed over a solid substrate with appropriate ice and water shield, or in limited applications over framing sections. When used in a windscreen application, panels must be fastened (stitched) through side joints. Consult a local architect/engineer for requirements of local codes and conditions.

Leveling

Petersen’s Flush panels are formed on precision roll-forming equipment that includes levelers. Leveling removes typical metal conditions including coil set, crowning and edge wave. Leveling is available at no extra charge.

Trim

All flashing and trim shall be fabricated by manufacturer or qualified fabricator. Flashing shall be PAC-CLAD aluminum (.032 – .063 gauge as specified) or PAC-CLAD steel (24 gauge or 22 gauge as specified). A 30-year non-prorated finish warranty can be supplied covering finish performance. Vinyl masking is recommended on all fabrication applications where extra handling is expected.

Optional clip

An optional patented concealed fastening clip is available to raise a panel assembly’s wind resistance performance level. The optional clip has been designed and tested to resist disengagement during high-wind events (clips were tested only on the 12-inch panel but can be used on all widths); consult Petersen factory rep for details.

Made from 24 gauge stainless steel, the clip is designed for use with PAC-CLAD Flush panels. Clips should be installed at the desired spacing per the product load table for the wind resistance requirements of the project.

The optional concealed clip, which is not visible when the installation is complete, is ideal for installations with higher wind-loading requirements that cannot be met without the clip. The clip can be installed on all substrate materials. The clip has passed multiple performance tests and earned Florida Product Approval. The clips are not to be used to reduce oil canning but rather to strengthen the panel in high-wind applications.

NOTE: Consult with Petersen rep or nearest manufacturing facility before specifying this clip.